Welcome to Ismat Engineering

Rubber Extrusion

Rubber Extrusion

Products made from rubber extrusion are frequently employed in industrial settings. Since it is resilient, elastic, and flexible, it is a good choice for applications involving fluid transmission, shock absorption, and sealing.

In the construction sector, extruded rubber profiles are used in a variety of sealing and gasketing applications. To suit certain end-use requirements involving variables like size, tolerance, configuration, cost, and performance, they are offered in a variety of compounds and forms.

Ismat Engineering is known for producing custom rubber extrusions of the highest caliber. We will go above and beyond your expectations because of our meticulous attention to detail, dedication to quality, experience in the field, and industry expertise.

Rubber Profiles

Rubber stripes and profiles are the most popular products in the rubber extrusion production line. Profiles and stripes come in a wide range of shapes, sizes, and rubber materials. We produce both solid and sponge types.

Profiles are used as anti-friction sealing components for the smooth operation of windows and doors. These rubber profiles are widely used in a wide variety of applications. These rubber profiles primarily function as sealants between the glass and aluminum sections.

The images below show some examples of the profiles that we manufacture. As custom manufacturers, we design and develop rubber profiles to meet our customers’ specific needs.

Rubber Packing’s

In the shipping industry, they are primarily used as watertight gaskets for hatch covers. These packings are made of sponge rubber as well as solid rubber and come in a range of hardnesses ranging from 40 shore A to 85 shore A.

Rubber packings are made from oil and weather resistant polymers such as Neoprene, Nitrile, and EPDM, as well as Silicon and Viton in some cases.

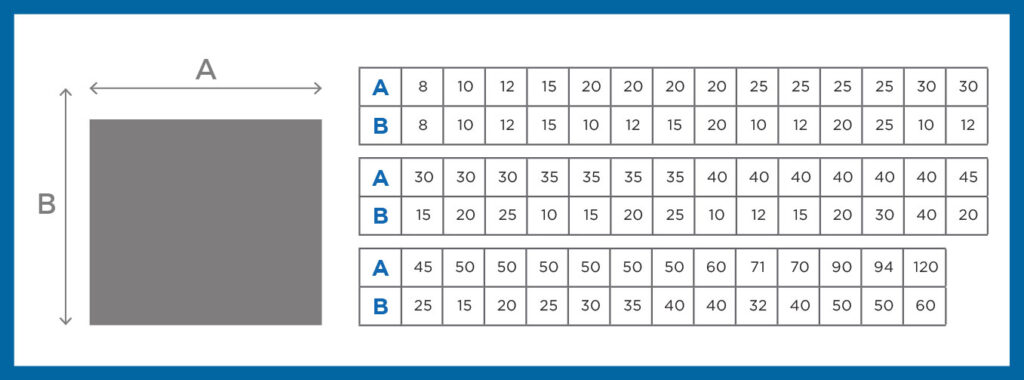

The standard packing sizes are as follows.

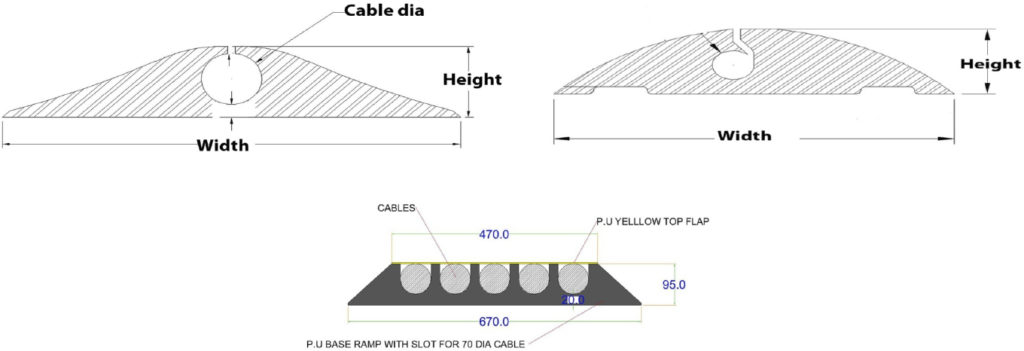

Cable Protectors

Our cable protectors are designed to withstand heavy vehicle and truck traffic.

Typically used to protect electrical cables on highways and construction sites.

These cable protectors are made for demanding work conditions and are made of high tensile and abrasion resistant polymers.

Apart from standard cable protectors, we also specialize in custom-made designs to meet individual needs based on specific work conditions and cable specifications.

Rubber Cords

In areas where the sealing is not too aggressive or under very high pressure, round rubber cord is a good alternative. These cords can be easily installed in inaccessible work areas and joined on-site with adequate adhesive. They offer adequate resistance and elasticity in sealing applications.

NBR Nitrile Rubber Cord

Hydraulic oils, water/glycol emulsions, oil in water emulsions, animal, mineral, and vegetable oils, fuels, and heavy oils are all compatible with NBR cord. They have excellent mechanical properties and a low compression set.

However, they are not suitable for high temperature applications, ozone protection, ketones, esters, aldehydes, chlorinated and nitro hydrocarbons.

EPDM Rubber Extruded Cord

Applications include steam, hot water, air, UV, diluted acids, and non-mineral oil bases.

Temperatures ranging from -50°C to +150°C can be tolerated.

EPDM Sponge Rubber Cord (Closed Cell)

Viton FKM Rubber Cords

This rubber cord is resistant to a wide range of corrosive fluids at elevated temperatures without significant degradation.

Viton rubber cords have excellent ozone and oxygen resistance, as well as good mechanical properties and a low compression set.

Can be used in demanding work environments with temperatures ranging from -25°C to +200°C.

Silicone Rubber Cord

Silicone Cord can withstand temperatures of up to 210°C. They have excellent insulating properties and are physiologically neutral. They can withstand temperatures ranging from -55°C to +200°C.

They have low tensile strength, as well as poor tear and wear resistance.