Call Us Now

+971 55 558 1873

Email Us

husaintambawala@ismateng.com

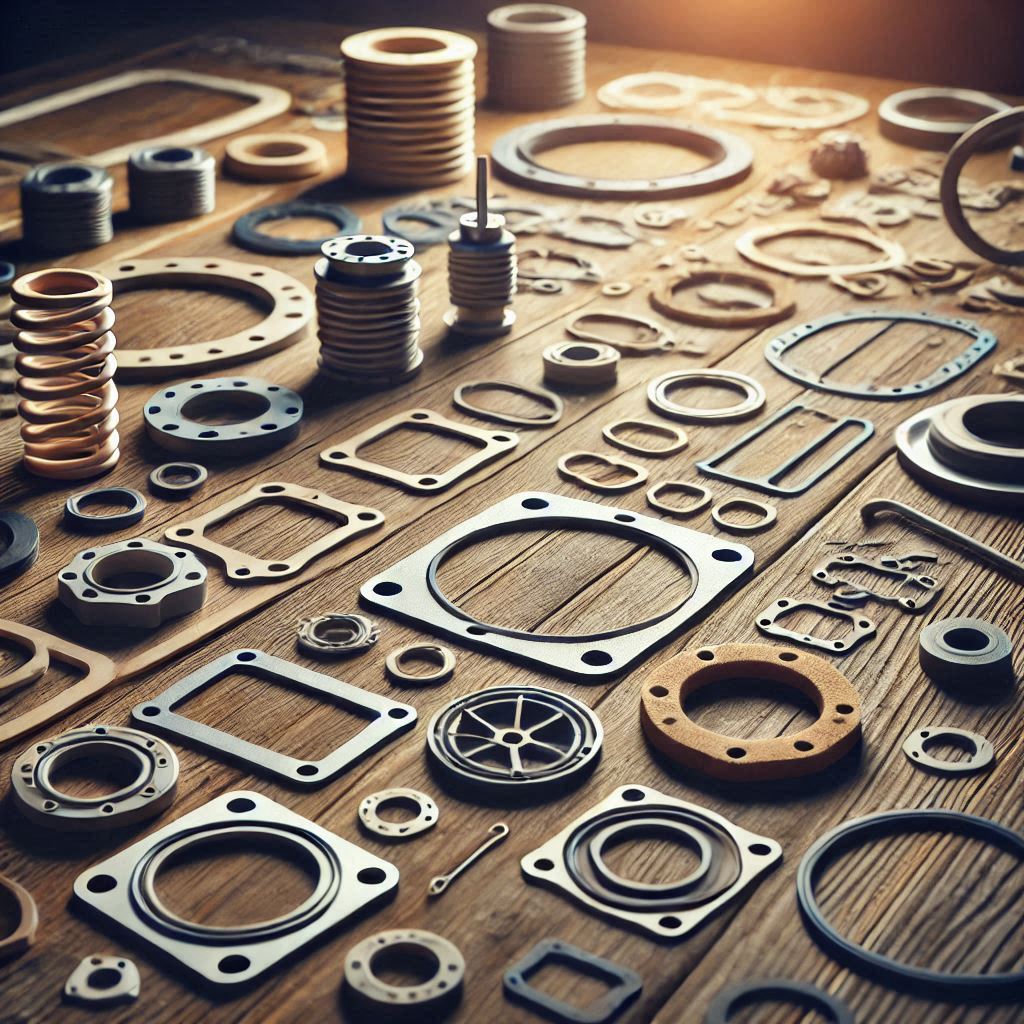

Premium Gaskets for Every Application – Precision-Cut, High Performance, and Reliable Sealing.

At Ismat Engineering in Sharjah, we specialize in delivering custom gasket solutions tailored to your specific sealing needs. Whether you’re working in oil & gas, marine, HVAC, food processing, or industrial maintenance, our high-performance gaskets ensure secure and long-lasting sealing under any condition.

Custom Solutions from Ismat Engineering

🔧 Our Gasket Product Range

✅ Custom Gaskets

We manufacture custom-made gaskets in any size, shape, or material based on your application. Using advanced cutting and fabrication technology, we ensure tight tolerances, flawless fitment, and rapid turnaround times.

- Precision CNC die-cut or hand-fabricated

- Available in paper, rubber, graphite, non-asbestos, PTFE, and metal-reinforced options

- Compatible with flange, pump, and equipment seals

✅ Paper Gasket Sheets

Ideal for light-duty applications, paper gaskets offer excellent compressibility and are cost-effective sealing options.

- High-temperature and oil-resistant grades available

- Used in carburetors, gearboxes, compressors, and light flanges

- Easy to cut and install

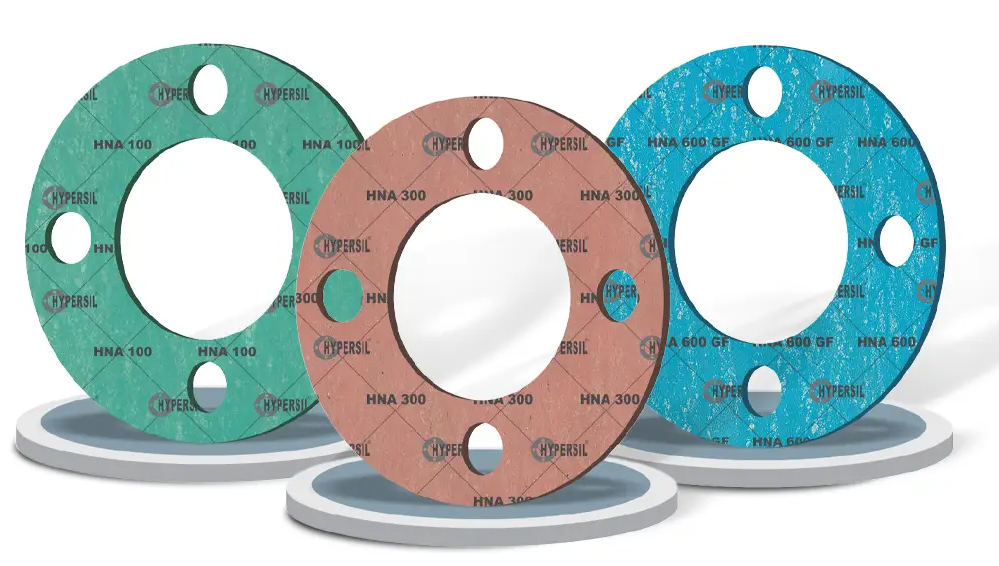

✅ Non-Asbestos Gasket Sheets

Safe, durable, and environmentally friendly alternatives to asbestos gaskets.

- High resistance to heat, pressure, oil, and chemicals

- Ideal for automotive, chemical, and industrial machinery applications

- Grades available: Aramid fiber, cellulose, and inorganic fillers with rubber binders (NBR/SBR/EPDM)

✅ Graphite Gaskets

For extreme environments, graphite gaskets provide outstanding thermal and chemical resistance.

- Operates in high temperatures up to 500°C+

- Excellent for steam, gas, and high-pressure lines

- Available in reinforced (tanged stainless steel, foil, or mesh) and non-reinforced forms

✅ Ring Gaskets

Designed for high-integrity pressure-sealing applications such as flanges and pipe joints.

- Precision-machined to meet ANSI, API, and DIN standards

- Materials: Non-asbestos, spiral wound, graphite, and metallic options

- Ideal for oil & gas, refinery, petrochemical, and heavy industrial sectors

Industries We Serve

Our gasket solutions cater to a wide array of industries, including:

- Oil & Gas

- Marine

- Automotive

- HVAC

- Manufacturing

- Power Generation